The global energy landscape is undergoing a radical shift. Driven by the surge in AI data centers and renewable energy integration, electricity demand is projected to grow at a compound annual rate of 5.8% through 2026. This massive requirement has turned power distribution equipment into strategic assets. Today, sourcing high-quality units from a reliable oil-immersed transformers supplier or a high-capacity dry-type transformers manufacturer has become a top priority for global EPC projects and industrial upgrades.

Technical Excellence of Oil-immersed Transformers

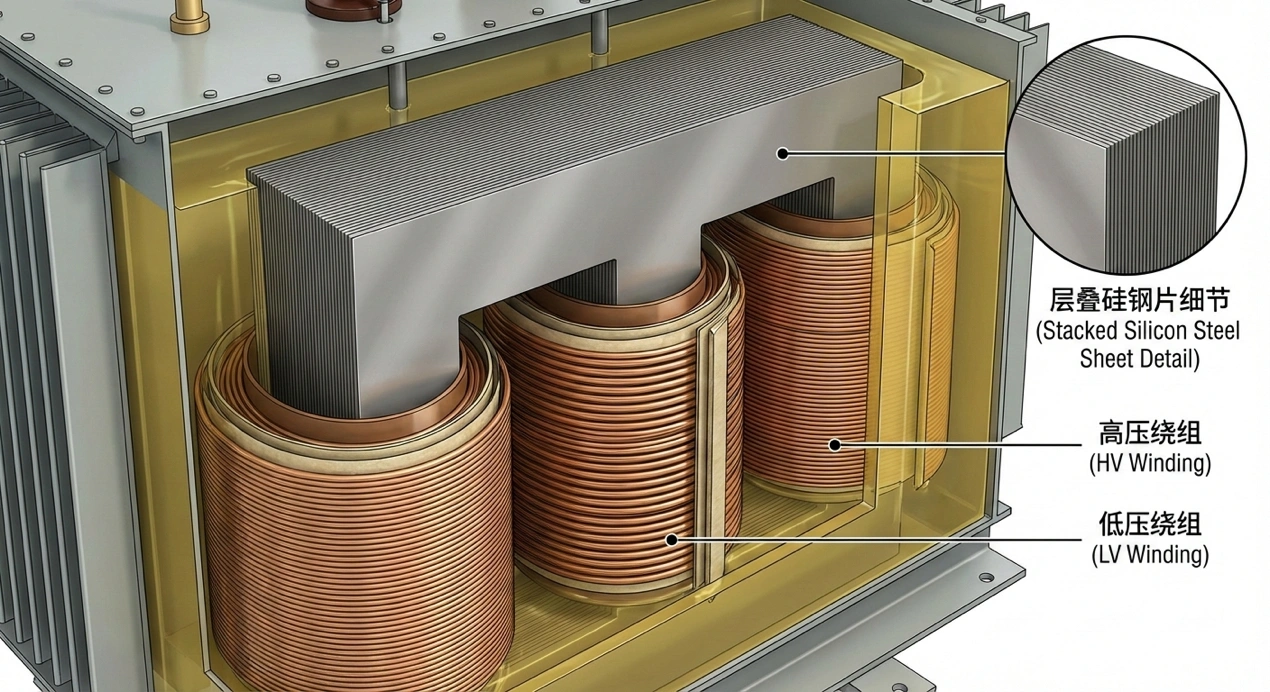

For heavy-duty industrial applications, the oil-immersed transformers remains the gold standard due to its superior heat dissipation and overload capacity. From a technical perspective, a premium oil-immersed transformers factory utilizes core laminations made of silicon steel sheets with a thickness of 0.35mm to 0.5mm. These sheets are coated with high-strength insulation paint to minimize hysteresis and eddy current losses.

The internal architecture is equally precise: high-strength copper or aluminum windings are arranged with the low-voltage winding positioned closer to the iron core to optimize insulation efficiency. Furthermore, advanced safety features such as Gas Relays, Explosion-proof tubes, and precise thermometers are standard. Operators must pay close attention to the 80°C alarm threshold for top oil temperature; a sudden rise of 10°C above normal levels often indicates internal faults like core ignition or coil short-circuits.

The Rising Demand for Dry-type Transformers

While oil-filled units dominate outdoor substations, the dry-type transformersis the preferred choice for indoor environments, high-rise buildings, and data centers where fire safety is paramount. As a leading dry-type transformers manufacturer, we understand that these units rely on natural air or fan cooling (AF), eliminating the risk of oil leaks or explosions.

With data center power consumption expected to reach 580TWh by 2028, the efficiency of dry-type transformers—specifically their ability to handle nonlinear loads—is critical. When sourcing from a dry-type transformers factory, buyers should verify the insulation class (typically Class F or H) to ensure the equipment can withstand the rigorous thermal demands of modern digital infrastructure.